Dutch Technology for high-efficiency n-type solar-cells

July 1 2012 – June 30 2014

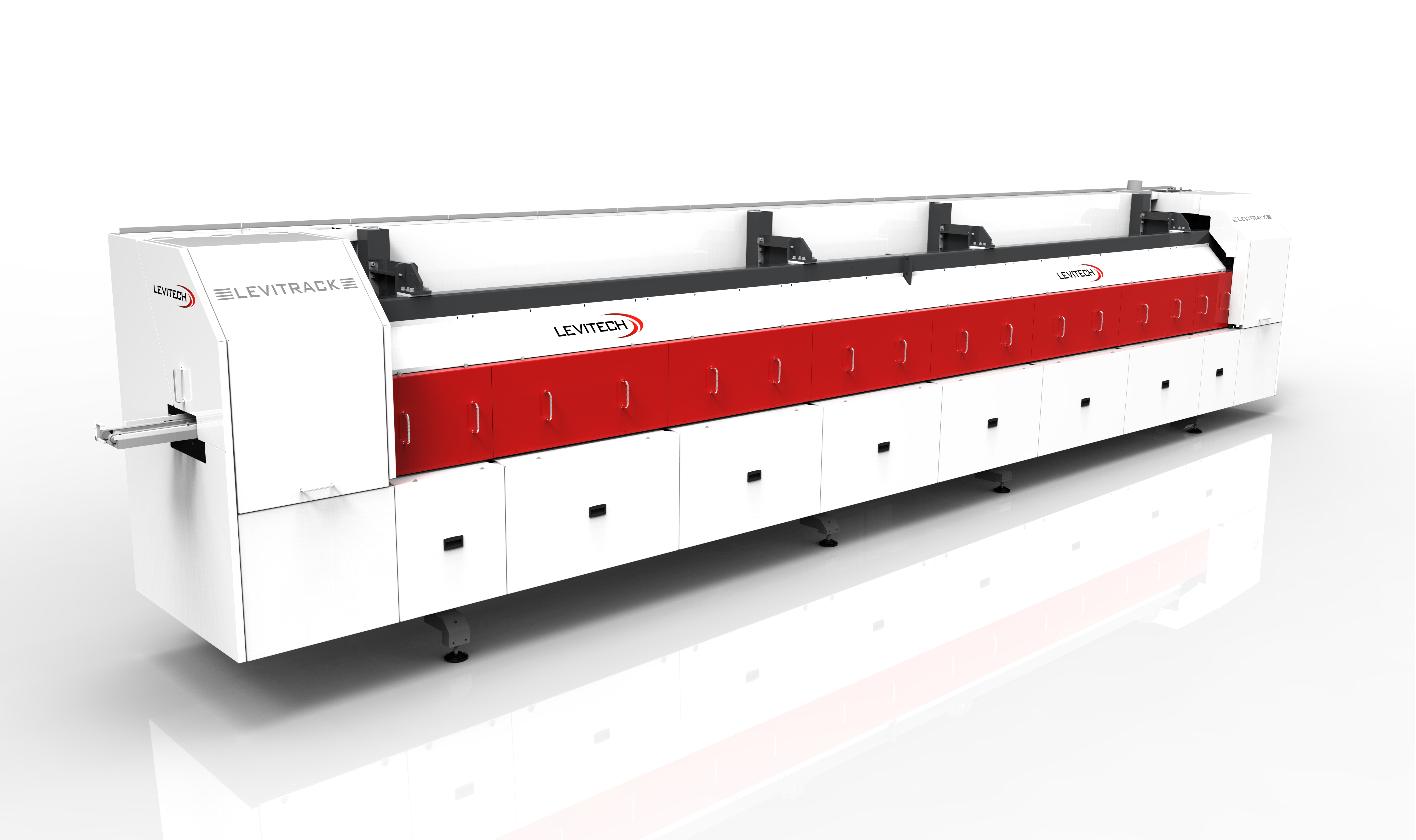

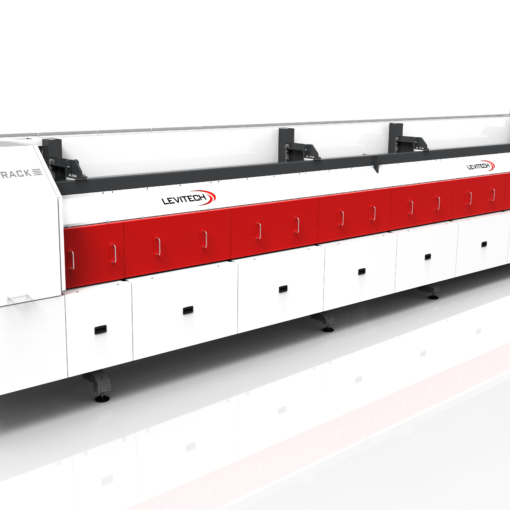

In this project new technologies for the production of highly efficient, crystalline silicon N-type solar-cells will be investigated and developed. For the participating companies Tempres, ASM, Levitech, OTB and MECO, it is important that their production equipment can be tested as part of a complete solar- and module- manufacturing process. Using this method, new and optimized processes can be directly validated in the areas of higher efficiency and lower costs. The participating Dutch companies supply all of the important aspects in solar-cell production line.

Project Targets:

- The Dutch Technology partners will develop equipment and processes and optimize those with regards to yield, throughput and quality to make the production of 21% N-pasha solar-cells for 21 $ct/wp and 22.5% n-IBC solar-cells for 25$ ct/wp possible.

- the newly developped equipment will be integrated in a complete solar-cell production line for 21% N-pasha solar-cells, with a throughput of 2800 wafers/hour and an improved yield, which will result in ~120 MWatt per year.

To realize these targets, the following subjects will be investigated and developped:

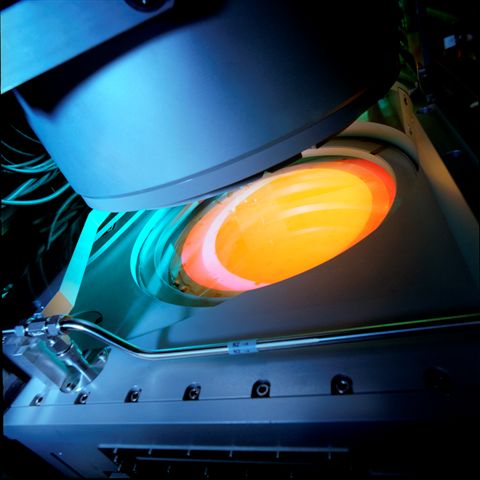

- The creation and patterning of the P-N-junction by new technologies like Ion-implantation, APCVD deposition and epitaxial Si-growth of doped Silicon by the companies ASM, Tempress, OTB, ECN and TUD.

- The improvement of the passivation of silicon surfaces with varying doping characteristics, by utilizing new technologies like industrial ALD of Al2O3 or by forming SiOx-layers by the companies ASM, Levitech, Tempress, OTB, ECN and TU/e

- The improvement of the contacting of Silicon surfaces with varying doping characteristics, by utilizing advanced metalization-technologies like inkjet printing, or forming Ni-Si contacts by the companies OTB, Levitech, MECO and ECN

- .The integration of the named processes to achieve 21% N-pasha solar-cells for 21 ct/Wp and 22.5% N-IBC cells for 25 ct/Wp.

For the development of all equipment, 6×6 inch N-type Cz silicon wafers will be used as the standard. The optimization of the equipment in the area of quality, yield and throughput will be governed predominately on the N-pasha solar-cell, as current “workhorse” of N-type cell technology. The potential in the area of quality will be evaluated through the production of higher efficiency N-IBC solar-cells

Voor de ontwikkeling van alle apparatuur zullen 6×6 inch2 n-type Cz silicium wafers worden gebruikt als standaard. De optimalisatie van de apparatuur op kwaliteit, yield en doorvoer zal voornamelijk worden verricht op de n-pasha zonnecel, als huidige ‘werkpaard’ van de n-type cel technologie. De potentie op gebied van kwaliteit zal verder worden beoordeeld door het produceren van de hoge efficiëntie n-IBC cellen.