Emitter Wrap Through cell concept: Evolution towards 20% industrial mc-Si solar cells

January 1 2010 – December 31 2013

The market for solar electricity is dominated by crystalline silicon solar cells and modules that have a market share of over 90%. The market share of so-called multicrystalline silicon solar cells is close to 50%. For lower cost-price of crystalline silicon PV, the industry focuses on higher effiencies and lower costs per Wp. To overcome drawbacks of available cells Solland and ECN started to develop a back contacted cell concept MWT (Metallization Wrap Through). In this concept the emitter is still contacted by fingers at the front surface.

The aim for this project is to research and to develop a main new step in solar cell concepts and includes three targets:

- The concept should be suitable for thin and cheap wafer material (< 150 μm, new wafer material like RGS)

- The concept should lead to a solar energy conversion efficiency for mc-Si solar cells of 18%, with a potential efficiency of 20%

- Using this concept the module costs should be lowered beyond € 1 / Wp (grid parity)

In order to reach these targets the EWT (Emitter Wrap Through) concept will be developed. In this concept all metallization is removed from the front surface, reducing the shading losses to zero and giving the cells a homogenous appearance. The emitter is led to the rear via a large number of holes and at the rear surface emitter and base areas are interdigitated and can both be contacted. Since the emitter is at the rear side as well, this concept could be better suitable for lower quality material like RGS since the need for high carrier diffusion lengths is less important.

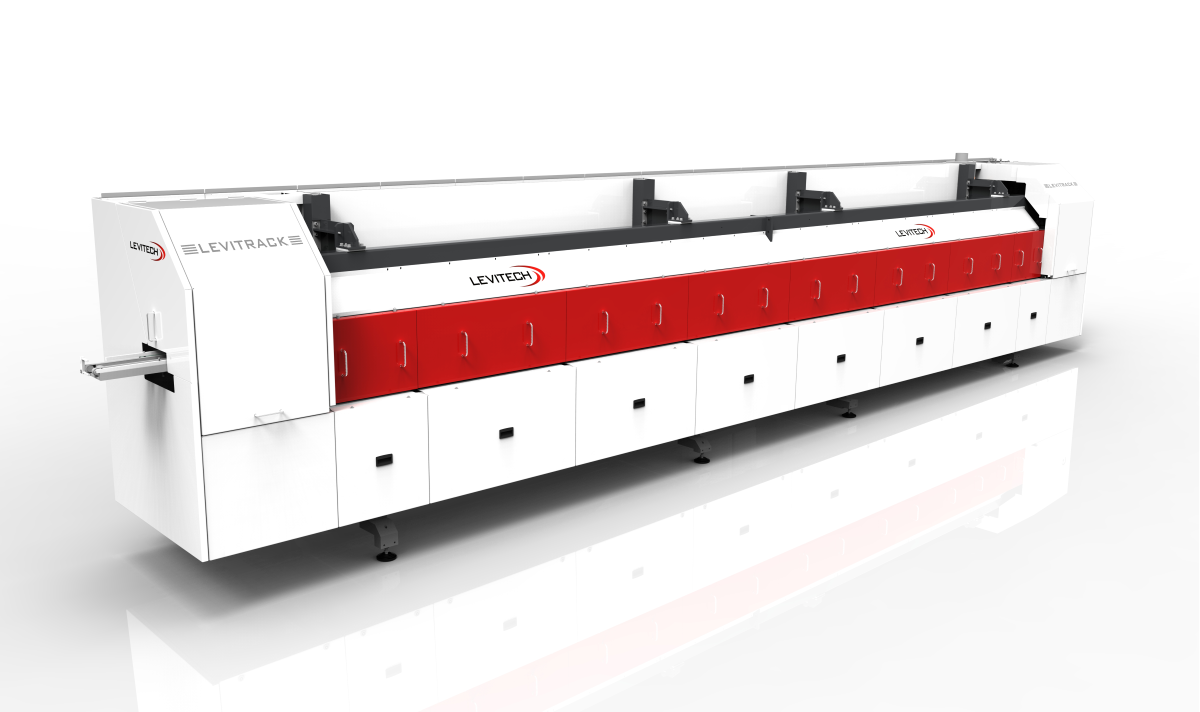

The project is charachterized by an integrated approach covering a large part of the vale chain, i.e . material, equipment and the product. In order to make the project usable for commercial developments after the project, commitment of several partners is required. Therefore Solland, as a developer and manufacturer of solar cells, has brought together a research organization (ECN), a new developer and manufacturer of equipment (Levitech) and a developer and manufacturer of RGS wafer material (Sunergy). The composition of the consortium is new and well balanced. Each partner is leader of one work package at least. The R&D activities will be performed within the framework consisting of six work packages.