April 1, 2014 – March 31, 2016

N-type cell and module technology in the Netherlands.

Even though solar electricity products have seen a significant growth in the past years, the introduction of novel technologies is needed for further cost and price reduction, and to maintain the current learning curve in order to keep one step ahead of the competition. Hence, the future competitiveness of cell and module concepts relies ever more on innovation towards high efficiency, cost effectiveness in $/Wp and reliability. This provides challenges but also huge opportunities for (Dutch) manufacturers of the enabling equipment and high-volume-manufacturing tools.

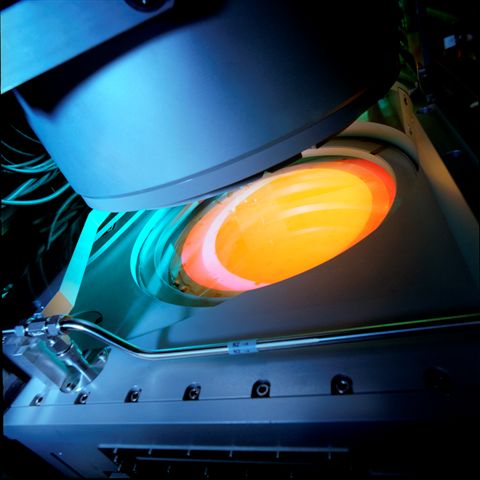

The NChanted project aims to continue to develop and demonstrate low-cost and high-throughput process technology for high efficiency n-type solar cells. First of all, the focus will be on understanding and implementing necessary improvements that can enable 21% n-Pasha cells. Processes identified as enabling higher efficiencies or lower costs in the currently running TKI Solar-project Dutchness will be industrialized in this project. Secondly the focus will be to develop additional processes and equipment for n-type front junction cells with efficiencies up to 22%

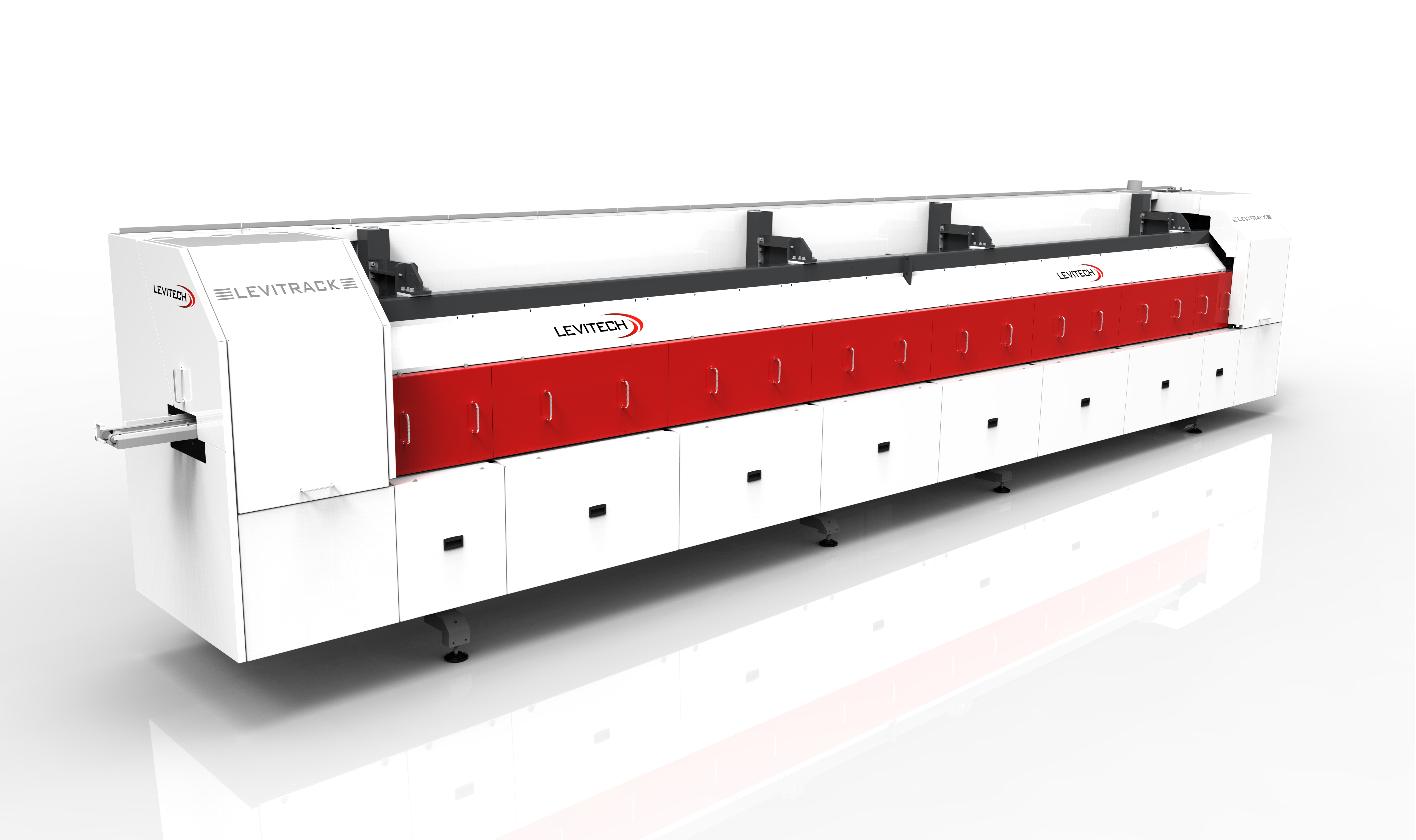

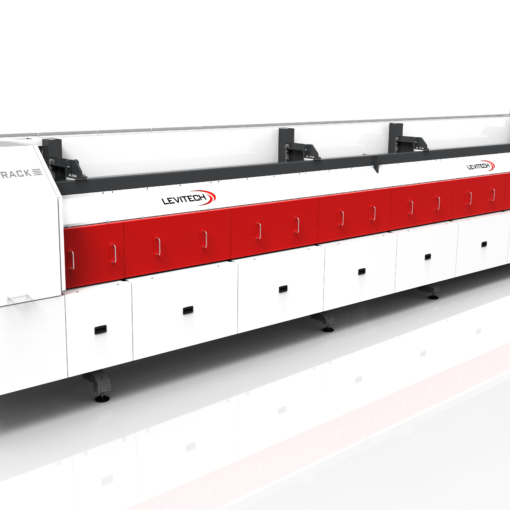

The companies involved in this project all have stakes in the n-pasha technology being developed further towards low cost and high throughput technology, as their equipment will depend on this to (further) penetrate the market. Where Tempress will work on diffusion and passivation equipment and methods, Levitech will focus on spatial ALD equipment and processing of improved passivating layers and ASM will focus on batch ALD equipment and processing of similar layers. Meco’s plating technology is required to replace the current state of art high-temperature metallisation steps, while R&R will contribute to processes for patterning of layers. The TU/e will contribute with their knowledge on advanced surface passivation schemes. TU/e will work on novel passivation layers and stacks for silicon solar cells to show that these layers can add value to PV technology. Furthermore, TU/e will develop analysis and characterization methods for various passivating schemes and apply those on structures developed in this project. ECN will focus on full integration of the new developed processes (emitter /BSF formation, patterning, passivation and metallization) in high efficiency n-Pasha cells, and on other high efficiency n-type front junction cells. Furthermore, ECN will focus on implementing the n-Pasha cells in bifacial modules to make optimal use of its optical properties

The integration of technological developments on processes and equipment at a cell level will be done in WP1. Within this WP1, ECN will execute several full cell runs per year for this purpose, in which the innovations on doping, passivation, metallization and structuring from WP2 – 5 will be judged on efficiency gain and cost effectiveness. Furthermore, in WP1 simulations will be done on the n-Pasha cell structure to identify bottlenecks and points for further improvements. The first target of WP1 is to obtain a cost effective n-Pasha cell of 21% efficiency that can be directly transferred to industry; secondly a front junction n-type cell, which enables efficiencies up to 22% in the lab, using industrial processes, will be targeted.

In the subsequent WPs 2 – 5, the work will focus on the specific processing and equipment innovations. In WP2, different doping techniques for emitter and BSF will be researched, while in WP3 various passivating layers and concepts are investigated. WP4 will govern metallization, with the focus of NiSi formation by plating and subsequent anneal. In WP5 patterning of doping profiles as well as patterning of dielectric layers for subsequent metallization will be researched. The focus of WP2 – 5 will lie at the industrial partners that will develop and built the equipment and at the TU/e who will take a more fundamental approach to the passivation and analysis of the various layers in WP3. During the various stages of development, evaluation of specific processes will take place on a limited amount of n-Pasha solar cells, half fabricates or n-Cz wafers. For full evaluation of optimized processes, complete cell runs including a baseline reference will be performed in WP1

In WP6, the n-Pasha and later-on other n-type front junction solar cells will be integrated into bifacial modules at ECN. At ECN, typically small test modules consisting of 4 or 6 cells will be fabricated to be able to test the performance (energy output, cell to module loss) of newly developed processes and n-type cell designs on a module level. Furthermore, reliability and degradation tests will be done. At the end of the project, a full size 60-cells module will be fabricated (at a third party) for demonstration purposes at exhibitions.